Mt Deans Project location plan in the Eastern Goldfields Lithium corridor

The licence covering the Mt Deans Project (P63/2063) was granted in September quarter 2019. The lease was subject to an earn-in JV with Lithium Australia NL which expired in mid 2020, resulting in the Project reverting to Aruma 100%. Aruma holds a positive view of the lithium, tantalum and REE potential of the Project area with previous work having identified swarm pegmatites over 1km in length.

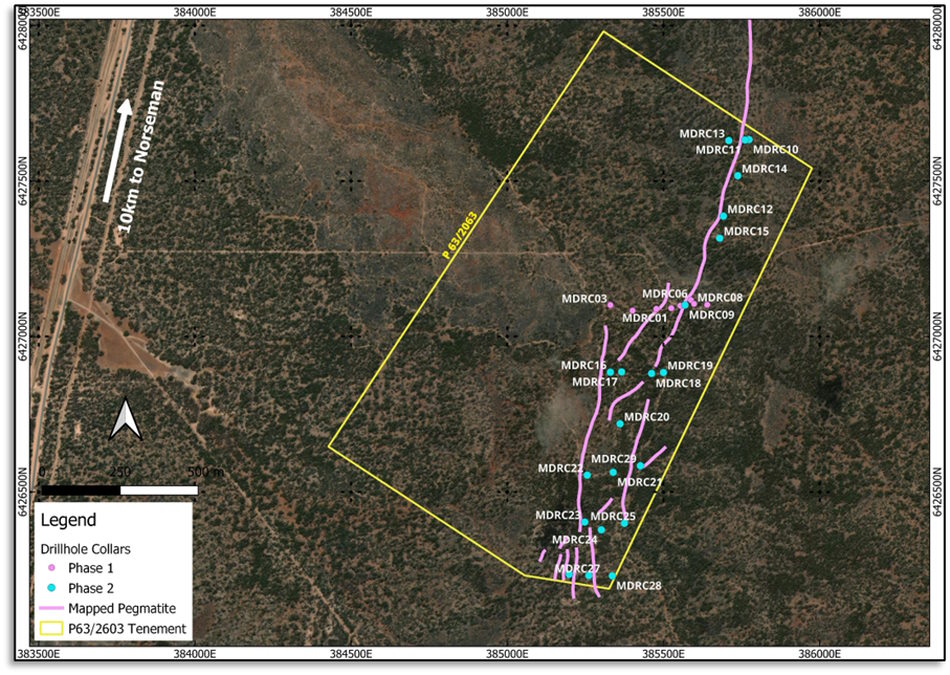

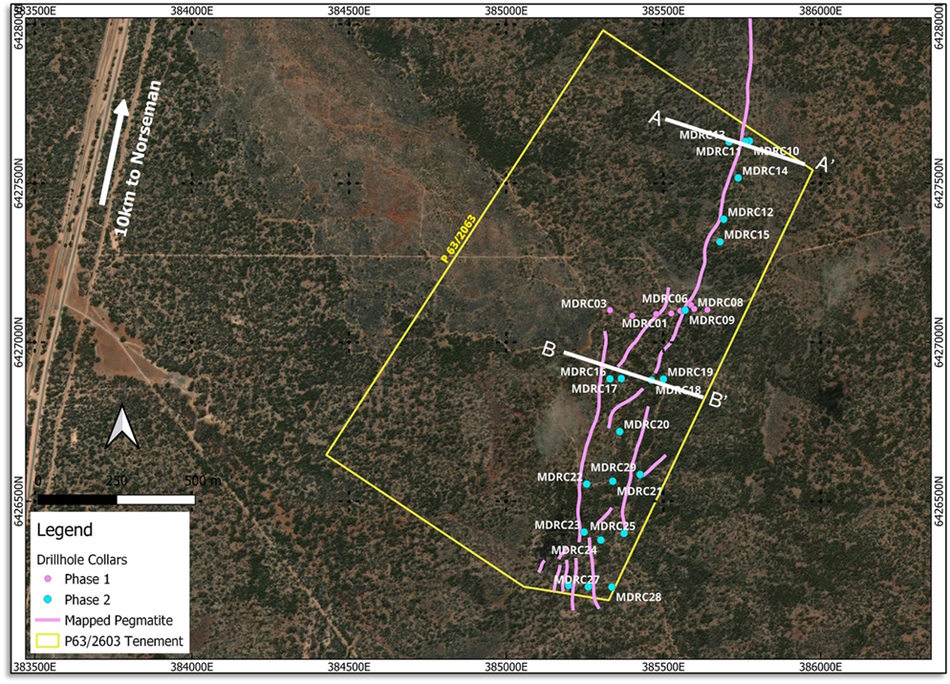

The Mt Deans Project covers an area of 1.44km2 in the Mt Deans pegmatite field, which is part of the Eastern Goldfields Terrane of the Yilgarn Craton. The Project is located approximately 190km north of the Esperance port, 170km south of Kalgoorlie and approximately 10km south of the mining town of Norseman (below).

The geology at Mt Deans presents as potentially analogous to that of Liontown Resources’ (ASX: LTR) world-class Kathleen Valley Lithium-Tantalum Project in the Mid-West region of WA, where the lithium mineralisation is hosted within spodumene-bearing pegmatites.

The Mount Deans pegmatite field covers an area of 6 kilometres north-to-south and 4 kilometres in extension east-to-west and comprises multiple individual pegmatite sheets and lenses. It is Archaean in age and hosted in the north-south trending Dundas Hill greenstone belt.

About the Mt Deans Lithium Project

The 100%-owned Mt Deans Project (P63/2063) is located in the Mt Deans pegmatite field, within the Eastern Goldfields Terrane of the Yilgarn Craton, approximately 170 kilometres south of the major regional centre of Kalgoorlie and approximately 10 kilometres south of the mining town of Norseman.

The Project sits within the lithium corridor in south-east WA, which hosts multiple significant hard-rock lithium projects. It is interpreted to sit within the same host rocks and structures as the significant nearby Mt Marion, Bald Hill and Buldania Lithium Projects (Figure 1).

Aruma’s Mt Deans Project contains lithium micas, not spodumene, as well as tantalum and tin with potassium and rare earth element (REE) minerals. These lithium micas are being used in China to produce some 0.5mt of Li2CO3 in Jianxi Province.It is situated in the Mt Deans pegmatite field, which produced tin in the 1960s, within the Eastern Goldfields Terrane of the Yilgarn Craton, approximately 170 kilometres south of the major regional centre of Kalgoorlie, and approximately 10 kilometres south of the mining town of Norseman (Figure 2).

The Mt Deans area has a swarm of 71 recognised pegmatites covering 4.5km by 1.5km trending north, north-west (as discussed in Amit Eliyahu’s University of Western Australia thesis on the Mt Deans pegmatites). The pegmatites range from 500m to 2,000m in length and 0.3m to 7.5m thick, with some 20m thick.

The pegmatites have an upper portion quartz-poor, feldspar-rich marginal layer, which is where most of the cassiterite and tantalum is found. The pegmatites in the project area are considered later (deeper) and are suggested to be closer to a main ‘cauldron’ or ‘chamber’ that may host spodumene-rich material, potentially suitable for direct shipping.

A prime example of this style of deposit is Liontown Resources’ (ASX: LTR) Buldania and Kathleen Valley lithium deposits, where finger-like thin, steep pegmatites coalesce into a thick spodumene zone at shallow depth.

Previous exploration has identified swarm pegmatites over a strike length of 1 kilometer. High-grade rock chip samples have previously been reported from the Project area, with lithium oxide results as high as 2.1% Li2O, and tantalum (Ta) as high as 556 ppm Ta2O5 (tantalum pentoxide) plus other rare earth elements (Table 1) (ASX announcement, 24 March 2021).

Commentary on Assay Results

Broad spaced drilling and surface sampling in 2022 by Aruma identified a thick vertical sequence of lithium and high-grade rubidium bearing pegmatites over a strike length of about 1.5 kilometres at the Mt Deans Project (Figure 2).

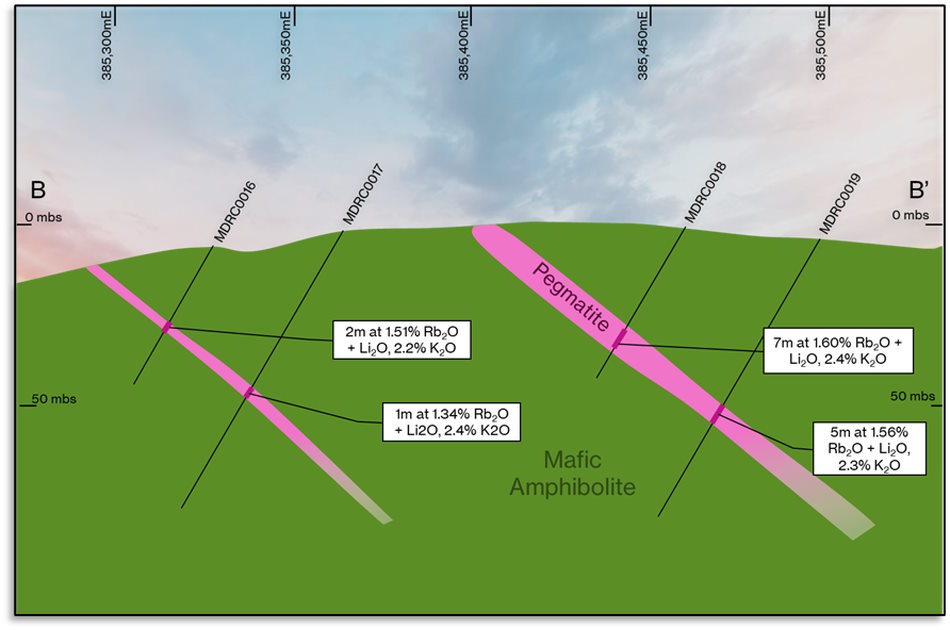

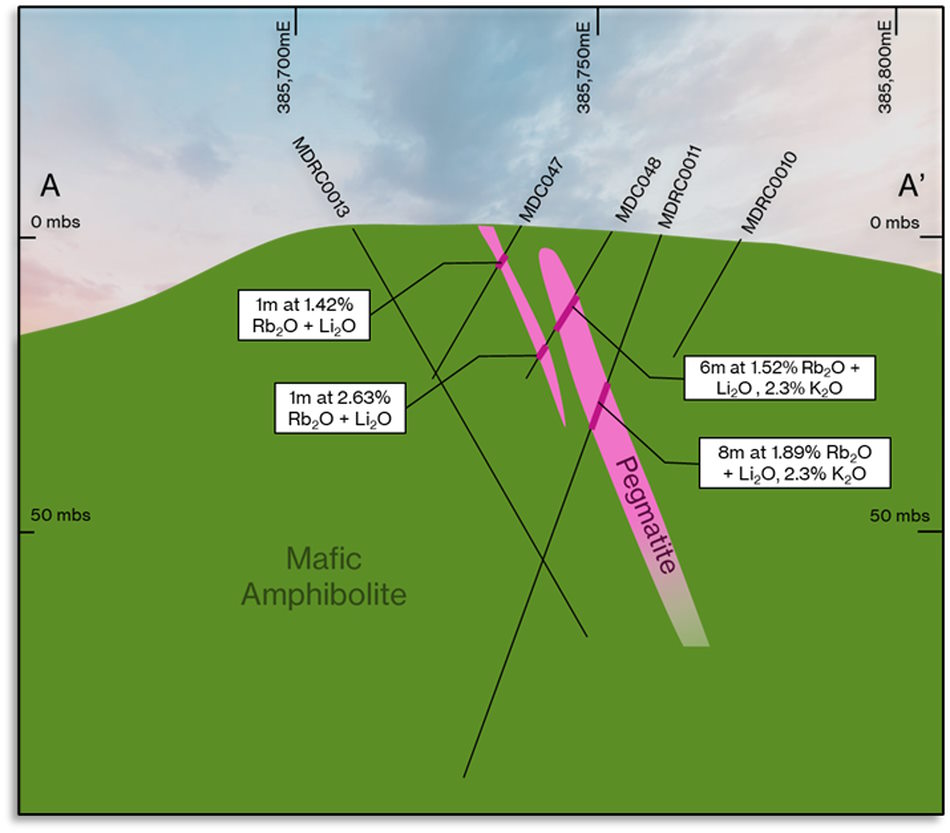

All assays have now been received and validated from the Company’s second phase of drilling. The remaining 19 holes from Aruma’s drilling and the seven historic holes which were re-assayed have all returned high grades above 1% combined Li2O and Rb2O in significant intervals, of 5 metres or more.

Table 1 Significant results for the final assays of all recent drilling. Results >1% Rb2O+Li2O. Values greater than 1.5% Li2O + Rb2O highlighted in Red.

| Hole ID | From | To | Width | Grade | |||||||

| Li2O % | Rb2O % | Li2O + Rb2O % | K2O % | Cs ppm | Nb ppm | Sn ppm | Ta ppm | ||||

| MDRC0003 | 3 | 5 | 2 | 0.63 | 0.55 | 1.18 | 1.8 | 531 | 37 | 118 | 209 |

| MDRC0006 | 31 | 38 | 7 | 0.75 | 0.69 | 1.44 | 2.7 | 384 | 33 | 240 | 165 |

| MDRC0007 | 144 | 150 | 6 | 0.51 | 0.60 | 1.11 | 3.0 | 273 | 32 | 180 | 85 |

| MDRC0009 | 33 | 42 | 9 | 0.27 | 0.96 | 1.23 | 3.1 | 616 | 21 | 239 | 36 |

| 46 | 51 | 5 | 0.28 | 0.77 | 1.05 | 2.6 | 486 | 19 | 296 | 32 | |

| MDRC0011 | 26 | 34 | 8 | 1.13 | 0.77 | 1.89 | 2.3 | 1167 | 45 | 201 | 360 |

| MDRC0014 | 33 | 38 | 5 | 0.73 | 0.71 | 1.44 | 2.7 | 845 | 44 | 157 | 359 |

| 55 | 60 | 5 | 0.77 | 0.75 | 1.51 | 2.7 | 3312 | 36 | 120 | 262 | |

| MDRC0016 | 26 | 28 | 2 | 0.78 | 0.73 | 1.51 | 2.2 | 568 | 33 | 115 | 184 |

| MDRC0017 | 53 | 54 | 1 | 0.71 | 0.63 | 1.34 | 2.4 | 365 | 29 | 139 | 115 |

| MDRC0018 | 33 | 40 | 7 | 0.98 | 0.63 | 1.60 | 2.4 | 376 | 31 | 405 | 135 |

| MDRC0019 | 55 | 60 | 5 | 1.02 | 0.54 | 1.56 | 2.3 | 274 | 40 | 326 | 166 |

| MDRC0021 | 63 | 69 | 6 | 0.65 | 0.50 | 1.15 | 2.4 | 333 | 33 | 179 | 99 |

| MDRC0022 | 18 | 23 | 5 | 0.78 | 0.58 | 1.35 | 2.4 | 343 | 30 | 216 | 143 |

| MDRC0023 | 11 | 13 | 2 | 0.62 | 0.63 | 1.25 | 2.7 | 537 | 154 | 154 | 139 |

| 23 | 25 | 2 | 0.71 | 0.61 | 1.32 | 2.7 | 348 | 36 | 176 | 121 | |

| MDRC0024 | 68 | 69 | 1 | 1.05 | 0.85 | 1.90 | 3.3 | 566 | 40 | 207 | 121 |

| 74 | 76 | 2 | 0.88 | 0.70 | 1.58 | 2.7 | 822 | 25 | 170 | 123 | |

| MRC047 | 7 | 8 | 1 | 0.86 | 0.56 | 1.42 | 1.9 | 581 | 26 | 135 | 152 |

| MRC048 | 12 | 18 | 6 | 0.83 | 0.70 | 1.52 | 2.1 | 2107 | 41 | 209 | 253 |

| 23 | 24 | 1 | 1.94 | 0.69 | 2.63 | 1.9 | 1110 | 41 | 201 | 234 | |

| MRC049 | 4 | 9 | 5 | 1.18 | 0.80 | 1.98 | 2.0 | 1022 | 58 | 204 | 372 |

| MRC050 | 9 | 13 | 4 | 0.75 | 0.58 | 1.33 | 2.0 | 580 | 33 | 151 | 279 |

| MRC052 | 4 | 6 | 2 | 0.86 | 0.80 | 1.70 | 2.7 | 806 | 43 | 243 | 299 |

| 20 | 28 | 8 | 0.94 | 0.66 | 1.60 | 2.2 | 588 | 31 | 240 | 210 | |

| MRC053 | 15 | 16 | 1 | 0.65 | 0.69 | 1.34 | 2.3 | 1025 | 51 | 116 | 399 |

| 46 | 52 | 6 | 0.65 | 0.57 | 1.22 | 2.2 | 352 | 30 | 204 | 221 | |

Note – Down hole widths.

As previously reported hole MDRC0011(Figures 2 and 3 and Table 1) intersected a pegmatite of approximately 5 metres true width, with consistent high-grade (1.13%) Li2O. The composited interval for this pegmatite is 8m @ 1.89% Li2O+Rb2O.

Also reported hole MDRC0009 (Figure 2 and Table 1) intersected a contact zone of altered mafic host rock and pegmatitic material. This zone is interpreted to be a mineralised alteration zone (“alteration zone”) on the contact between intrusive pegmatites and the mafic country rock. Within MDRC0009, the alteration zone is intersected over 32 metres downhole (at plus 0.8% Li2O+Rb2O), including two higher grade zones of 9m @ 1.23% Li2O+Rb2O and 5m @ 1.05% Li2O+Rb2O.

The Mica Types suggested in Figure 5 below demonstrates that the highest lithium grades (blue line) were in the pegmatite with highest Rb grades causing a reversal of the Li-Rb trend. This suggests the presence of another mineral, suggested by chemistry to be Rb mica or muscovite, The potassium levels are sympathetic to both lepidolite and muscovite occurring with the cesium peaks following the Rb in most cases.

The suggested distribution of the Li-Rb in two micas may potentially deliver benefits in concentrating the valuable elements in a mining operation, as they could be amenable to relatively simple and cheap floatation methods.

The zoning and grade distribution suggests that there are lepidolite rich pegmatites (high Li and Rb) and the contact material (low Li and high Rb) with a yet to be identified mineral. Mineralogy will be completed on drill samples to confirm these assumptions.

Conceptual Project Development Pathway

Based on the continuing positive results from its drilling and exploration activities at Mt Deans, Aruma may look to identify micaceous pegmatites with high-grade (>1.5% Li2O+Rb2O) Lithium-Rubidium-Cesium-Potassium ore, which, conceptually, may potentially be capable of being concentrated using simple froth flotation/gravity circuits to produce a saleable lithium-potassium concentrate, with valuable rubidium and cesium by-products with possible tin and tantalum gravity concentrates.